Material

Anthracite coloured, solvent-free sealing, adhesive & coating compound based on silicone. Once completely bonded, REINZOSIL is virtually odorless.

Properties

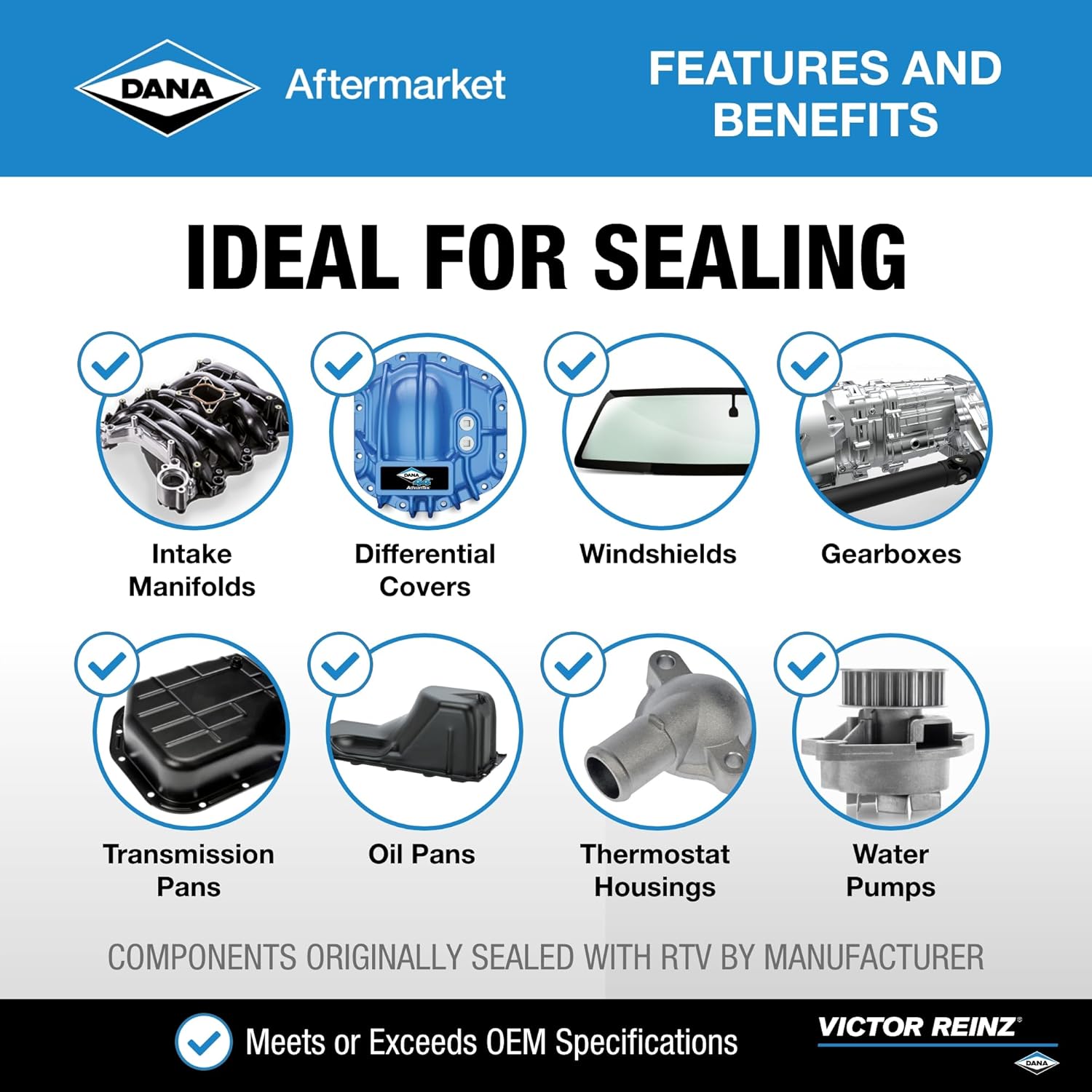

This highly elastic universal sealing compound is resistant to all mineral oils and numerous synthetic oils, lubricants, gasoline, diesel oil, greases, hot and cold water, cleaning agents, sunlight, ozone, and sea water.

There is no outgassing, i.e. no gas escapes from REINZOSIL highly elastic universal sealing compound under the effects of temperature, so it does not influence electronic sensors.

REINZOSIL is a neutral-bonding silicone, so it does not attack metallic surfaces, i.e. REINZOSIL does not trigger oxidation in its surroundings which can have negative effects on sensors, electronics, or electrical components. This makes REINZOSIL an ideal sealant for many housing components which cover sensitive electronics. This is what gives REINZOSIL its title “Sensor Safe”.

REINZOSIL can be used at temperatures from – 50 °C to + 250 °C in continuous running operation, and even as high as 320 °C for short periods of time.

Its hardness/softness ranges between 35 and 40 Shore A.

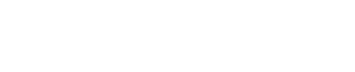

Features:

- Non-hazardous substance

- No damage to surfaces and sensors being oil-resistant, low volatility, non-corrosive, and low odor

- Cleanly bonds and seals to metal, vinyl, rubber, and plastic making it a leak-proof windshield sealant

- Resists friction modifiers in conventional and synthetic gear oils

- Easy application with fast curing abilities

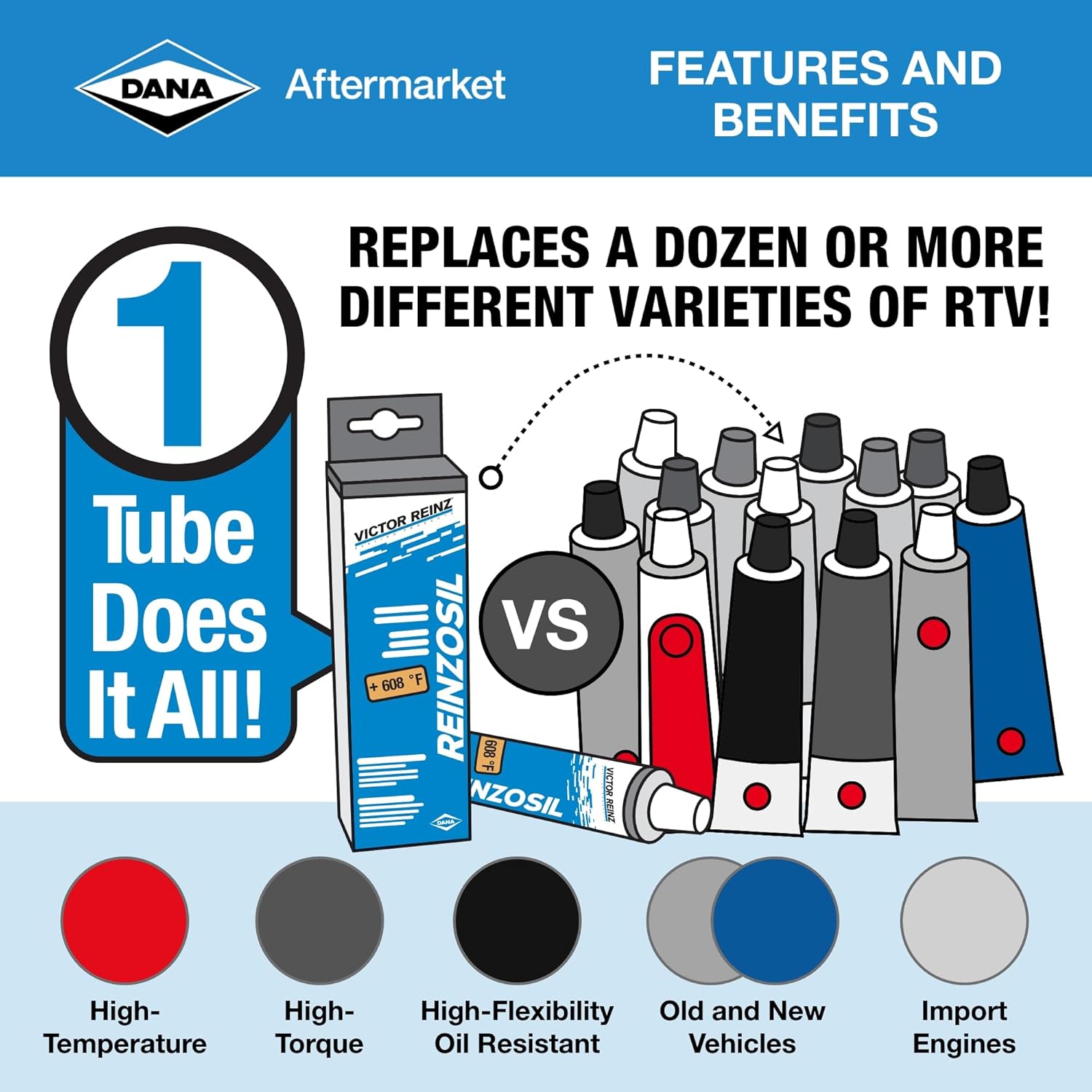

- Can be used to apply on RTV originally sealed components, such as intake manifolds, oil pans, and valve covers

- Can be used on 2D flat surfaces with up to a .15 mm sealing gap, example: gasket intersections

Specifications:

- Container Size: 70 ml

- Sealant Type: Silicone Gasket Maker

- Container Type: Tube

- Water Resistant: Yes

- Color: Black

Instructions for use

Remove any gasket remnants or other residues such as grease, oil, etc.

with REMOVE solvent remover. Allow the surfaces to dry, then apply the sealing compound on one side manually or by means of a pneumatic spraying device. Assemble the components immediately.

Processing temperature lies between +5 °C and +40 °C. Depending on temperature and humidity, a skin develops after 5 to 12 minutes. The full curing time depends mainly on the relative air humidity (RH) and room temperature, as well as on the thickness (gap height) and width of the applied layer.

Applications:

Due to its special properties, REINZOSIL is used in the most varied applications, e.g. as FIPG (formed-in-place gasket) for wet assembly, i.e. for sealing small gaps under pressure as well as for cylinder liners in piston machines, and also to compensate for extensive component warping. Moreover, the compound is also used to seal constructional

fissures or cracks, and for seals that are subjected to considerable relative movement.

Contrary to REINZOPLAST, the sealing layer is destroyed during disassembly, and a new coating is required after the surfaces have been cleaned.

The compound can also be applied to assembled components. In these cases, after the sealing joint has been cleaned and degreased, REINZOSIL is applied directly to the sealing gap, similar to the procedures used in the building industry

Reviews

There are no reviews yet.